Our Services

PIC PACKAGING, TESTING, FAILURE ANALYSIS & RELIABILITY TEST

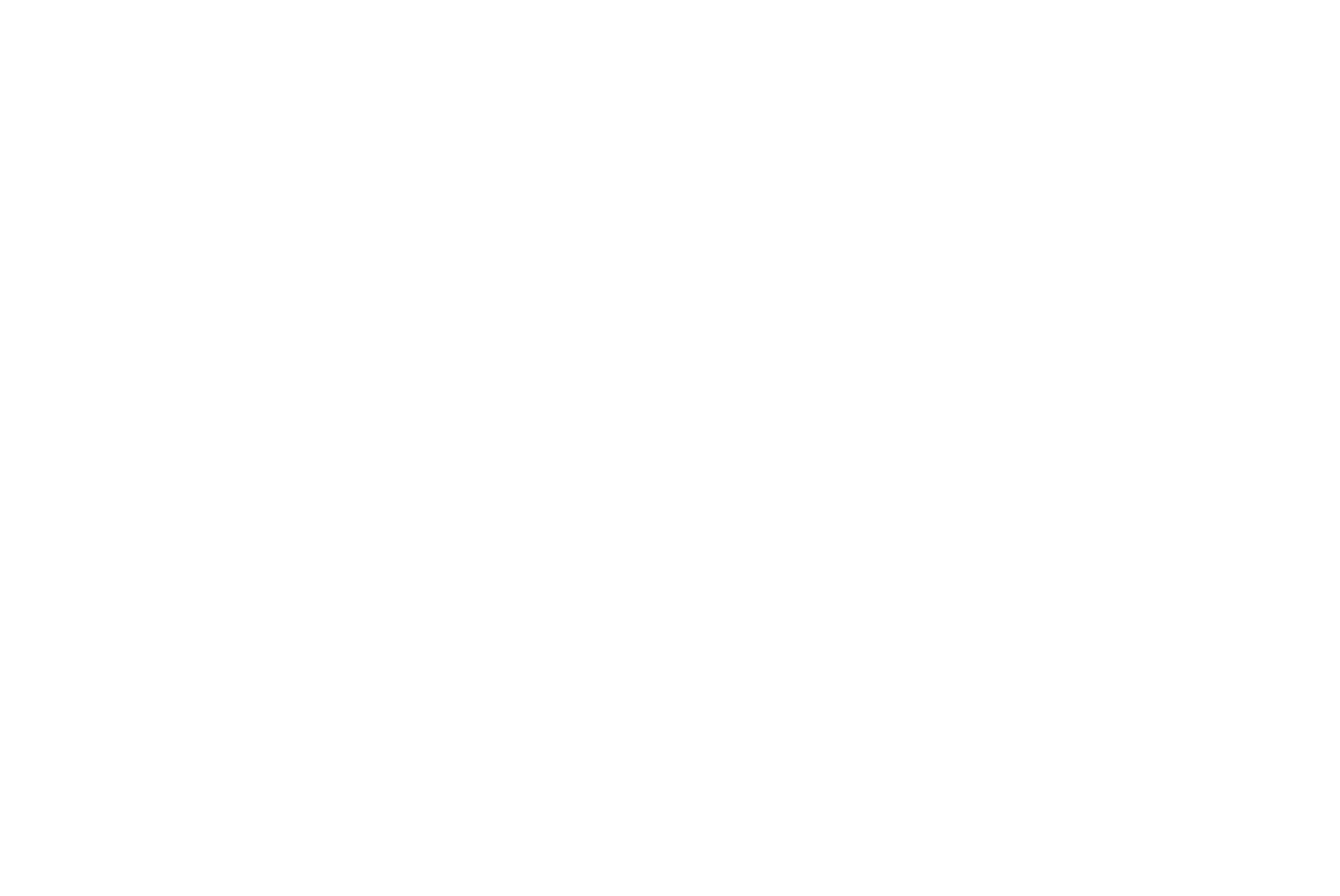

PIC testing is fundamentally different from electronic IC testing, requiring both electrical and optical probing with extremely high accuracy and precision. At Senphoton, through our strategic partners, we offer comprehensive testing services at both the wafer level (Wafer Level Testing) and die level.

Our testing capabilities include loss measurement: IL, PDL, and WDL (for both wafer and die), beam profile analysis (die level), and high-speed die-level characterization.

Additionally, through our strategic partners, we provide cost-effective and high-quality photonic die failure analysis (FA) and characterization services. We employ both destructive and non-destructive techniques such as SEM, FIB, AFM, and TEM to diagnose issues effectively.

Furthermore, we offer die-level reliability testing specifically for silicon photonics. Upon request, we conduct reliability verification to ensure your PICs meet the long-term performance requirements for your end products.

Key Highlights:

- Wafer Level and Die Level Testing

- Comprehensive Loss, IL, PDL, WDL, Beam Profile, and High-Speed Characterization

- Failure Analysis Using SEM, FIB, AFM, TEM Techniques

- Reliability Testing for Silicon Photonics

OPTICAL COMPONENTS

Through our strategic suppliers, we provide cost-effective and high-quality optical parts and components essential for your testing, assembly and packaging needs. Our product offerings include, but are not limited to:

Key Highlights:

- Vertical/Horizontal observation system camera, excellent low cost solution for your optical setup

- Customizable 3-axis micro-positioner for radio frequency (RF) probes or DC probes

- 14-pin narrow linewidth C-band tunable lasers

- Fiber arrays with customization options

- AWGs (Arrayed Waveguide Gratings)

- DFB III-V laser dies

Please leave us a message if you have other needs in your adventure.

PIC DESIGN

Senphoton specializes in designing Photonic Integrated Circuits (PICs) tailored to your technical specifications and requirements. As a fabless and independent design house, our expertise is in Silicon Photonics (SOI, thick SOI, SIlicon nitride, glass PLC). Whether you have a completed layout or just an initial idea, we will guide you through the entire process to ensure your vision becomes a reality.

Key Highlights:

- Photonic Material Expertise: Proficiency in Silicon Photonics, enabling versatile design options

- Proprietary Process Design Kits (PDKs): We utilize our proprietary PDKs and building blocks, ensuring optimal performance for your circuit systems with minimal risk.

- Industry Ready: Our designs are manufacturable and compatible with subsequent testing and packaging processes.

- Confidentiality and IP Security: We prioritize the protection of your information and intellectual property.

What We Offer:

- Custom Design Service

- Layout Service

- Design Support

- Customized PDK Development for Your Fab

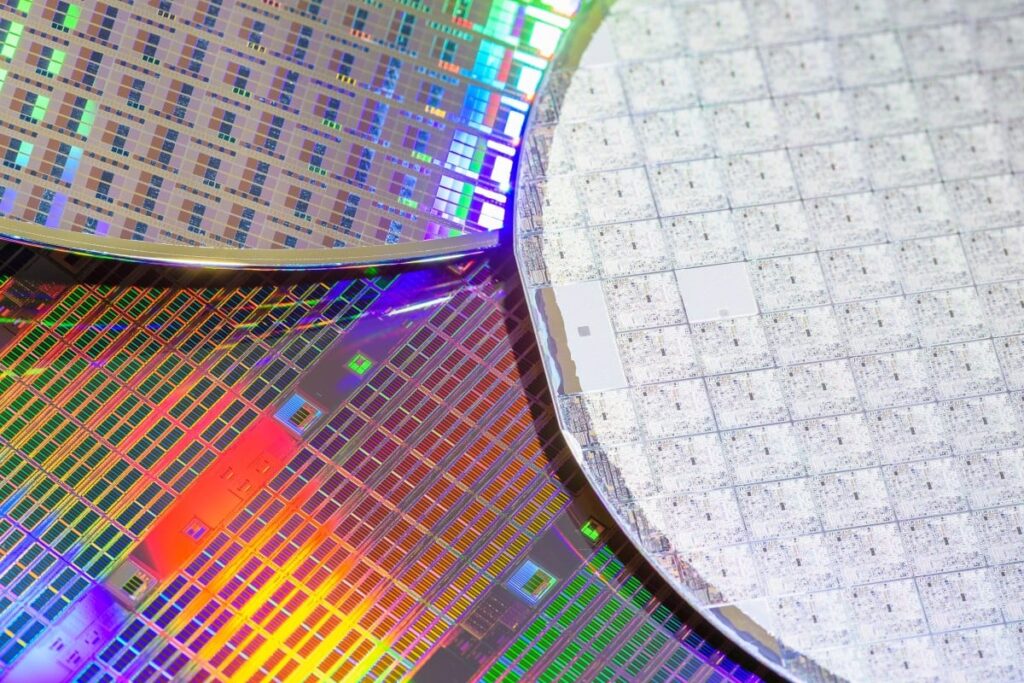

PIC FABRICATION

As a fabless design house, Senphoton brings extensive experience in working with foundries and pilot lines through strategic partnerships. We help you make the right manufacturing choices, whether you need a low-cost, rapid R&D concept validation, small-volume prototype production, or mass production of your validated products.

Through our close collaboration with leading foundries, we ensure the delivery of optimal solutions in terms of cost, timing, performance, reliability, and yield.

Key Highlights:

- Focused on PIC manufacturing in SOI, Silicon Nitride, and Glass PLC.

- Support for Multi-Project Wafer (MPW) and Dedicated Runs.

End-to-End Photonic Solutions Tailored for You

From PIC design to packaging and assembly, we provide expert support at every stage. Work with a team that understands your vision.